Wave solder pallet material manufacturer

The role of PCB wave soldering Frame

1. The role of wave soldering Frame

Wave soldering Frame is a very important auxiliary tool in the wave soldering production process. Its functions mainly include the following aspects:

1. Improve production efficiency

Wave soldering Frame can effectively improve production efficiency because it can help operators complete the soldering process of products faster. By using wave soldering fixtures, soldering time can be shortened and production efficiency will be improved accordingly.

2. Ensure welding quality

Wave soldering Frame can ensure the stability and accuracy of products during the welding process. It can help welders accurately position the welding position and maintain the stability of the component during the entire welding process. This ensures the welding quality of the product while reducing the incidence of ineffective welding or welding defects.

3. Reduce manual operation intensity

Wave soldering Frame can reduce the intensity of manual operations, reduce the operator's physical burden, and avoid operator fatigue during long-term welding processes. This can improve work efficiency and operation quality, reduce operator stress, and make the production environment safer and more orderly.

2. Choose the appropriate wave soldering Frame

Choosing the right wave soldering fixture is the key to improving production efficiency and product quality. When selecting, be sure to determine the shape and size of the fixture based on the shape and size of the product. In addition, the following factors need to be considered:

1. Material

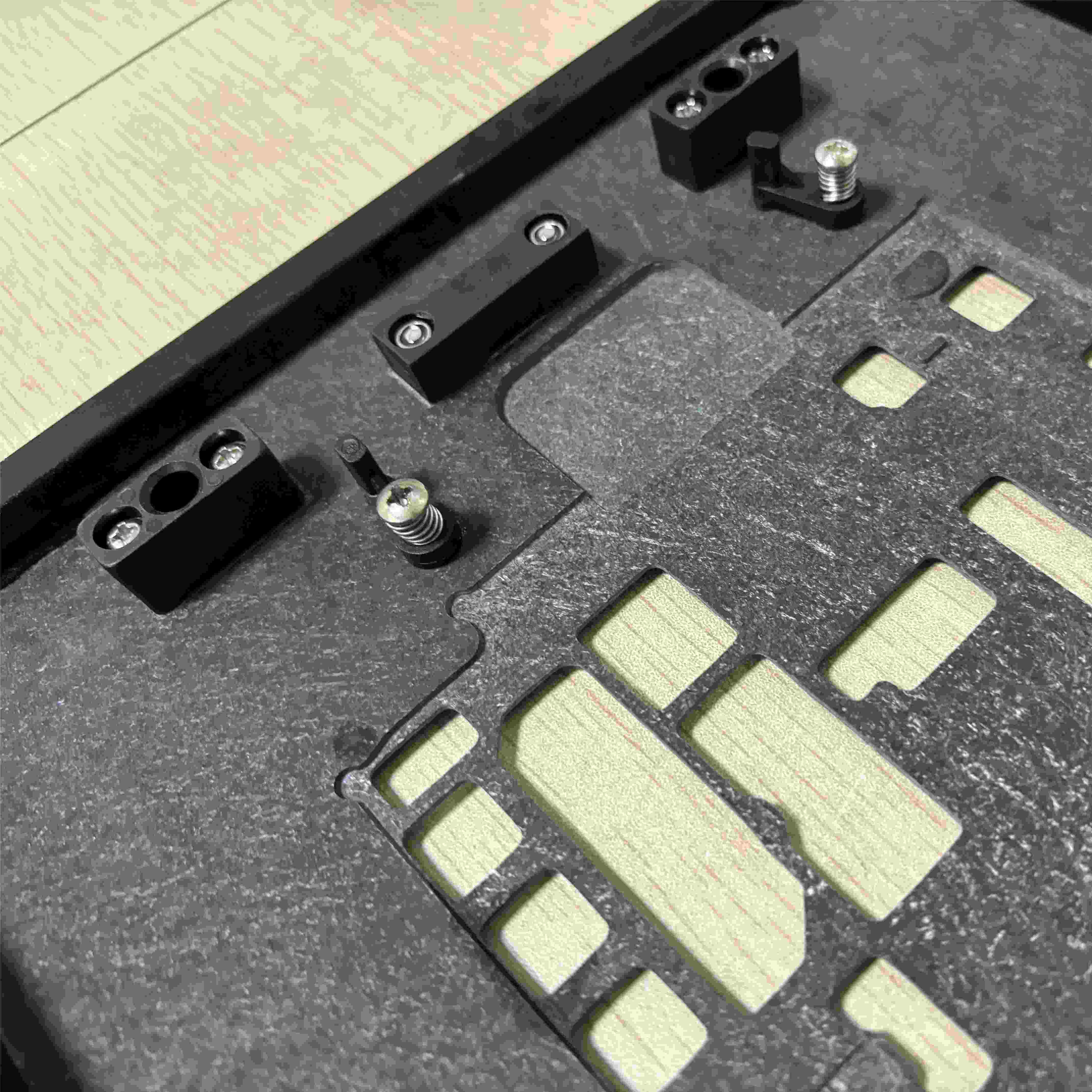

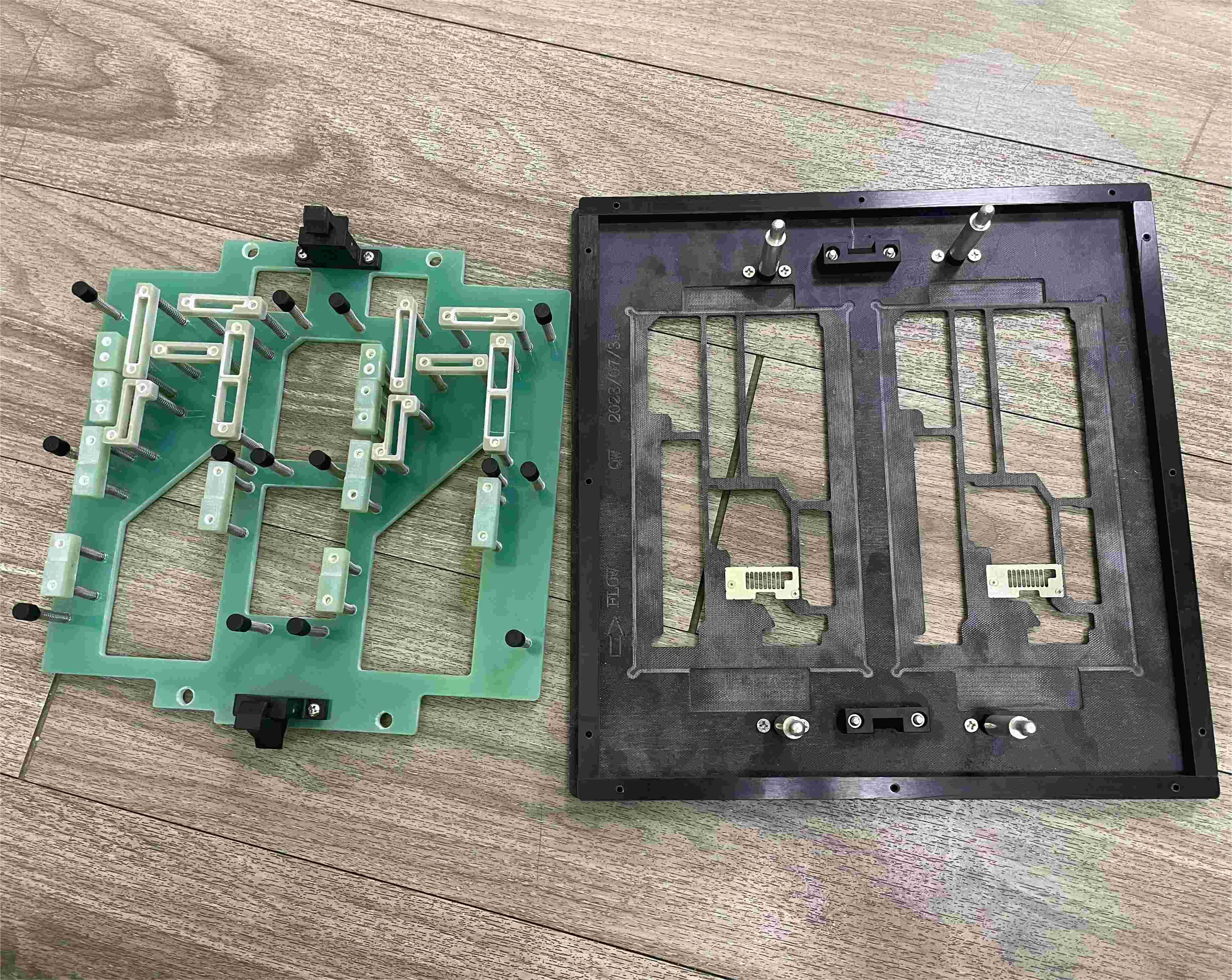

The material of the fixture can affect the welding effect and service life. The material should have properties such as excellent thermal conductivity, corrosion resistance, and wear resistance. For welding in high temperature environments, materials with better heat resistance can be selected, it can choose the material like durostone, ricocel, CDM for the PCB wave soldering frame.

2. Degree of standardization

It is necessary to choose fixtures with a high degree of standardization, so that when the process is optimized or the output increases, new fixtures can be quickly replaced to improve production efficiency.

3. Stability

The jig should have appropriate weight and stability, which can ensure the stability of the component during the entire welding process, thereby improving product quality.

To sum up, wave soldering Frame play a very important role in the PCB wave soldering production process. By selecting suitable fixtures, production efficiency and product quality can be improved, and the intensity of manual operations can also be reduced, making the production process safer, more efficient, and more stable.

The role of PCB wave soldering Frame

Flow solder carriers

SMT Carriers

soldadura pallet

SMT Matrix Tray

Selective machine pallets

SMT components trays

Surface Mount Carriers

Selective Solder Pallet?

Selective Wave Solder Fixtures

Standard & Adjustable Flow-Solder Carriers

Universal pallets

Universal Wave Solder Pallets

Wave Solder Pallets

Wave solder fixtures?

Wave solder tooling

Wave Pallets with Titanium Inserts

Wave solder frame

Durostone material

Ricocel sheets

CDM material

Engineering plastic material

Adjustable PalletsAssembly Fixtures

Adjustable Wave Pallets

Adjustable Wave solder Pallets

CDM ESD insulation sheet

Low Cost Surface Mount Carrier

Mobile Phone Test & Accessory JigsPCB PalletsPCB ToolingPCB router pallet materialPCB Test FixturesPress Tool FixturesPCB Alignment Plates

PCB wave solder pallet

PCB wave soldering frame

Wave soldering frame

Copyright © Dong Guan Noves Electronics Co., Ltd All rights reserved.

Tel : +86-15024113078 Fax :+ 86(769) 8202 5006

Add:No.20 Xinlang Road Huangjiang Town

Dongguan City Guangdong China